Main Line Kitchen Design does an analysis of the storage space advantage of frameless vs framed cabinetry.

.

Many customers select European frameless cabinetry over more classic framed cabinetry because they want additional storage. This isn’t surprising since the drive to maximize storage space in a kitchen is frequently the motivating factor for many kitchen decisions. However, often the reasoning behind these decisions is either flawed or the advantage is overvalued.

.

Let’s do some math to compare the additional space gained by using frameless cabinetry over more durable framed cabinet construction.

Frameless Cabinet

.

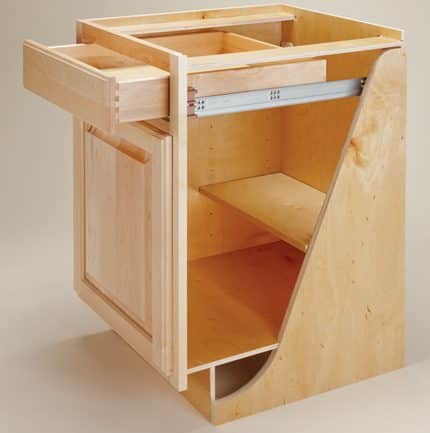

Above is a cross section of a cabinet built using the frameless method of construction. Notice the cabinet box is simply a back, bottom, top, and sides. The front of the cabinet is missing. Below is an example of a framed cabinet. Notice the front frame on the cabinet that the drawer passes through and that the hinges and hardware is attached to.

Framed Cabinet Box

.

Better made framed cabinets usually use 1/2″ thick sides and a solid wood face frame with horizontal and vertical pieces 1 1/2″ wide x 3/4″ thick. Better made frameless cabinetry uses 3/4″ thick sides and the cabinet has no front at all. This means that the hinges and drawer tracks are all attached to plywood or particle board sides on a frameless cabinet as apposed to solid wood on a framed line. However it also means that all roll outs, drawers, and pull outs must pass through the reduced size opening in the front of a framed cabinet.

.

What’s the difference in storage between the two options?

.

Lets do the math!

.

First the inside of both boxes are essentially the same since the width of the inside of a cabinet is identical in both framed and frameless examples. And while the frame does take up a tiny bit of space it is far less than 1% of the total cabinet space. It is only in the drawers and the roll outs that space is reduced significantly by the moving parts needing to pass through a smaller cabinet front opening. This also means that both framed and frameless wall cabinets contain the same amount of space. This is because it is only in the base cabinets and the bottom of the tall cabinets that drawers and roll outs can be used.

.

Each drawer or roll out in any cabinet will lose 3/4″ of space on each side so that the inside of every drawer in a framed line will be 1 1’2 ” narrower than in a frameless line. For an average cabinet of 24″ in width this means that the storage capacity of any drawer or roll out is reduced about 8%. More in narrower cabinets but less as the cabinet gets wider. So were a cabinet to have all drawers or all roll outs the most that the storage space would be reduced on average would be 8 %. A cabinet with only a top drawer would only lose storage space for that top drawer and the cabinet below would hold the same amount. So without roll outs a typical base cabinet with only a top drawer would lose at most 2% total storage. We are simplifying the calculations due to some other minimal factors we are not taking into account but we are also being liberal in the overall storage savings.

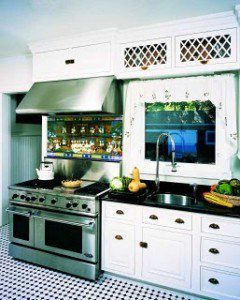

Framed beaded inset kitchen

.

Most kitchen use more drawers and roll outs today so assuming that the bottoms of most tall and base cabinets use drawers or roll outs lets say 6% of all the bottom cabinetry is lost. Since none of the storage in the tops of tall cabinets and wall cabinets loses space certainly the overall kitchen won’t lose more than 4% of it’s storage space using framed vs frameless cabinetry.

.

A 4% loss of storage space is not such a large number. By comparison choosing a range and a microwave hood above it in a kitchen can save 10% of the total storage in a small kitchen versus a design using a cooktop and a wall oven and microwave wall oven with a hood above the cooktop. Dividing cabinetry to create small spice pull out cabinets or tray divider cabinets can lose a similar 4% in a small kitchen. Even adding decorative 3″ wide legs on either side of a cooktop or sink would lose 5% of the base cabinet storage in a small kitchen. 10% if you did it in both places.

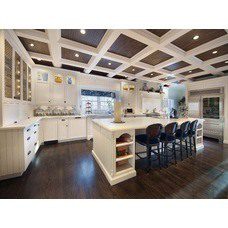

Contemporary acrylic European style cabinetry

.

Frameless cabinetry is less durable than framed cabinetry because there is no solid wood front on the cabinet. Cabinet fronts protect the cabinet box and frameless cabinet front edges are just 1/4″ thick edge banding at best. Having hinges and tracks screwed to the solid wood frame and screwing each frame to the faceframe next to it is what makes well made framed cabinetry capable of holding up over a lifetime. Face frames do get in the way which is why frameless cabinetry is also called “easy access cabinetry”.

.

Our take away from these space calculations and considering the durably issues is that we do not recommend using frameless cabinetry unless some of their other added benefits come into play. Most notably, there is no question that if you want very contemporary slab doors in your kitchen these modern styles look better on frameless European style cabinets.

.

Door and drawer gaps on frameless cabinets are 1/4″ tighter due to how the frameless hinges operate and that gap makes a big difference in making a contemporary kitchen look sleek, modern, and stylish. Because of this the most modern foil, acrylic, and laminate slab doors styles will only be available in frameless cabinet lines. However raised panel and recessed panel door styles like the popular shaker style look fine in framed lines.

Frameless modern “Steam Punk” styling

.

So before you jump into a decision of one cabinet construction type over another, consider your options and do the math!

Below are some related posts:

https://www.mainlinekitchendesign.com/general/what-cabinet-line-is-the-best/

https://www.mainlinekitchendesign.com/philadelphia-kitchen-cabinets/cabinets-buying-guide/

.

Hoping that you will let our designers help you with your calculations and as always . . .

Bon Appetit!

.

Paul, Julie, Ed, Chris, John, Lauren, Tom and Stacia

Main Line Kitchen Design

If you would like to check out all of our kitchen design topics, please visit the Reference Library

Schedule an appointment with a designer here.

.

.